Stainless steel Homogenizer mixing Tank

How the Vacuum homogenizer mixing tank works is very simple. the materials are introduced into the mixing tank.

The emulsifying mixing tank contains homoginizer impellers with slotted teeth, which promotes thorough mixing. During operation, the blades simultaneously rotate in forward and reverse rotation at variable speeds.

The equipment has the advantages of compact structure, small size, light weight, easy operation, low noise and stable operation. Its major feature is that it does not only grind the medium in the production process, but also integrates high-speed shearing, dispersion, homogenization, mixing, and crushing. Under the action of the centrifugal force generated by the high-speed and strong rotating rotor, the high-shear machine throws the material from the radial direction into the narrow and precise gap between the stator and the rotor, and at the same time is subjected to centrifugal squeezing, impact and other forces to disperse the material. Mixing and emulsifying.

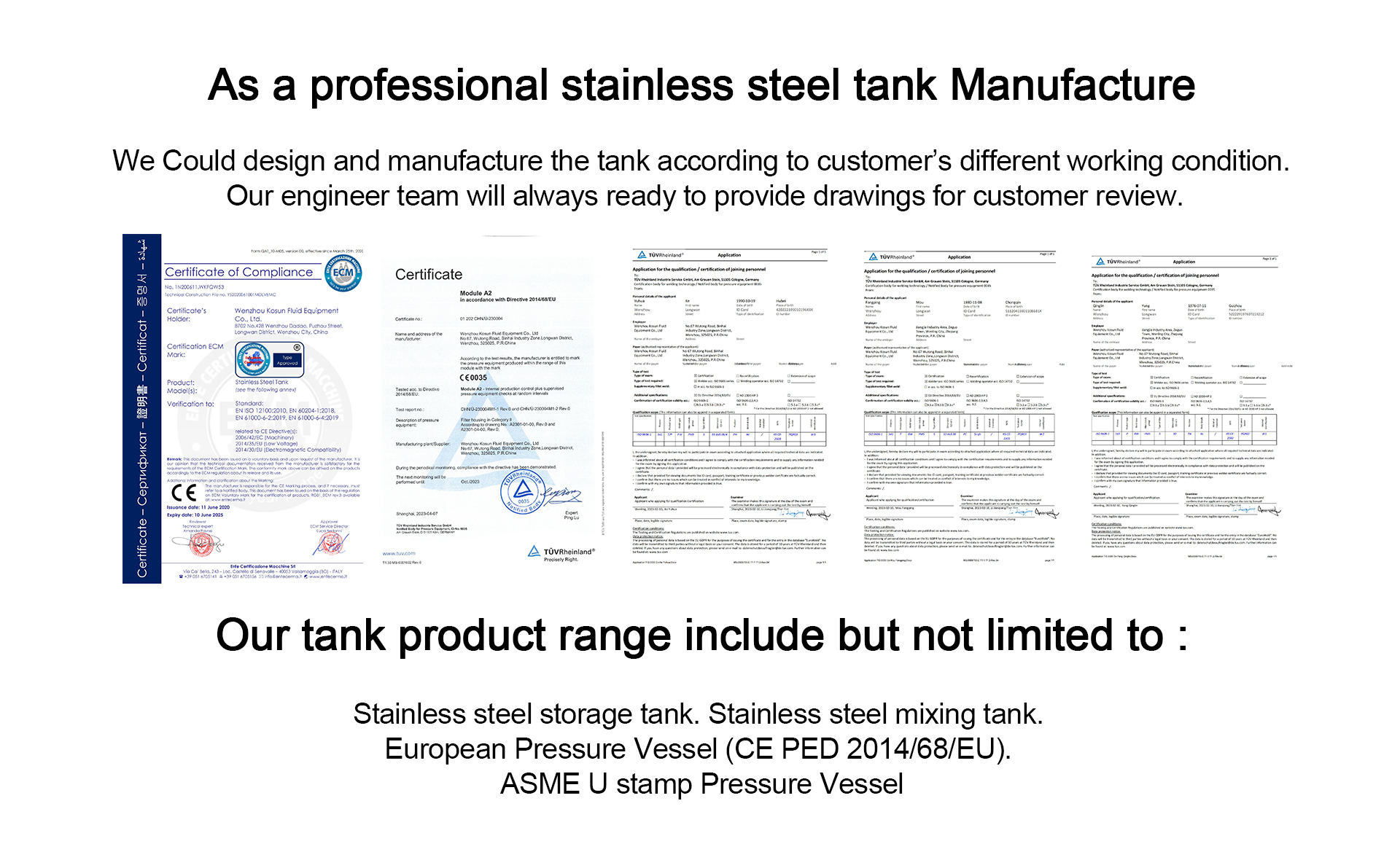

Please contact us with your specification of the tanks you want, Our engineering team will give you the best solutions!

|

Tank Data sheet

|

|

|

Tank Volume

|

From 50L upto 10000L

|

|

Material

|

304 or 316 Stainless steel

|

|

Insulation

|

Single layer or with insulation

|

|

Top Head type

|

Dish top, Open lid top, Flat top |

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

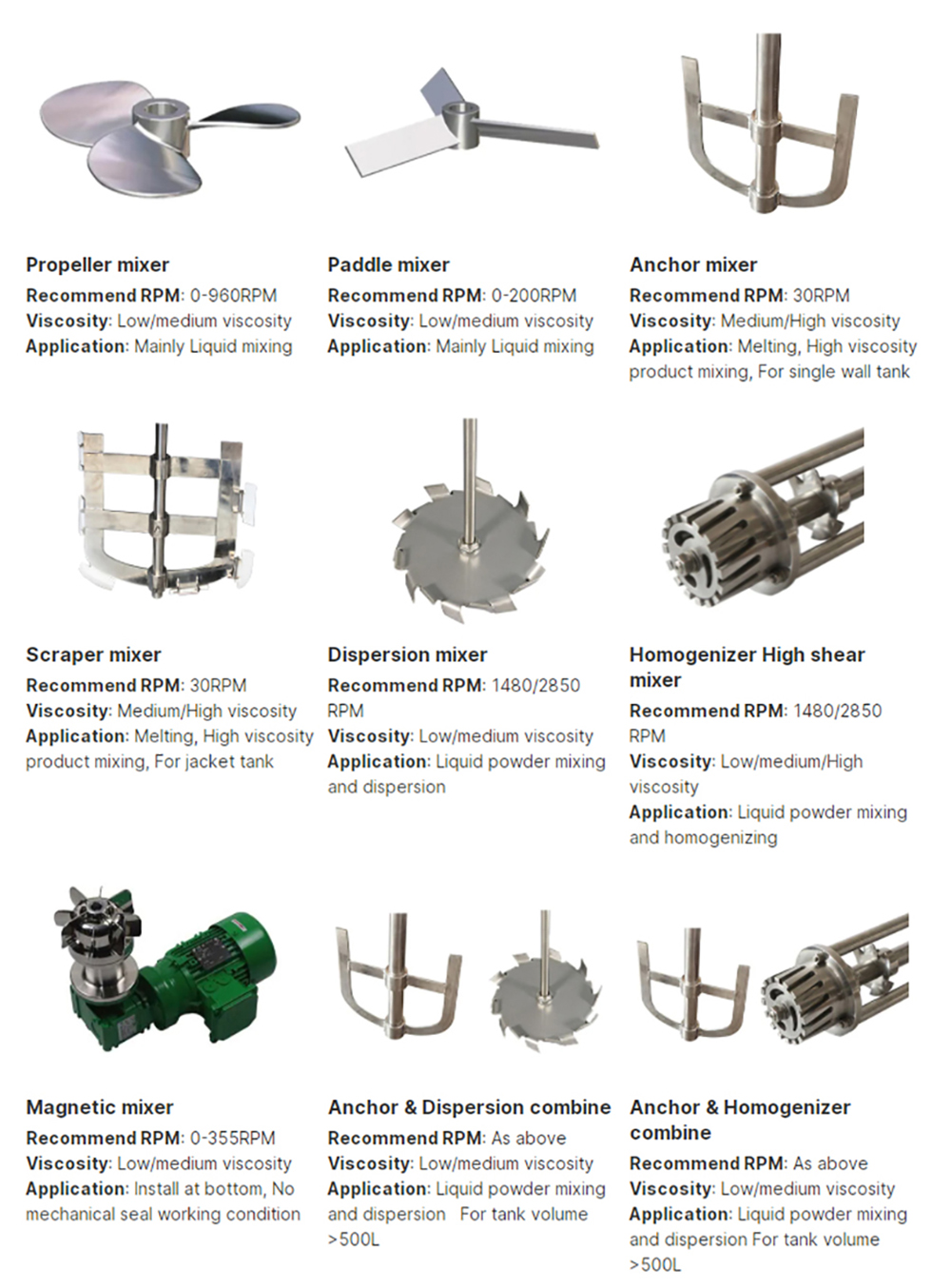

Agitator type

|

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

magnetic mixer, Anchor mixer with scraper

|

|

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

Outside Finish

|

2B or Satin Finish

|

|

Application

|

Food, Beverage, pharmacy, biological

|

|

honey, chocolate, alcohol etc

|

|

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur