Ingancin waldawar kabu na tankin ruwa na bakin karfe yana shafar amincin jirgin ruwa kai tsaye.Akwai hanyoyin walda da yawa, walƙiya argon arc yana ɗaya daga cikin ingantattun hanyoyin waldawa, amma lokacin da diamita ya fi 800mm girma kuma yana da girma sosai, kariyar cikawar argon na ciki yana kawo wasu matsaloli kuma yana haɓaka farashin samarwa.The biyu-baka argon baka waldi tsari ne yafi amfani da waldi na kewaye kabu da kuma a tsaye kabu na ganga, wanda muhimmanci inganta waldi ingancin da waldi yadda ya dace da kuma rage samar da farashin.

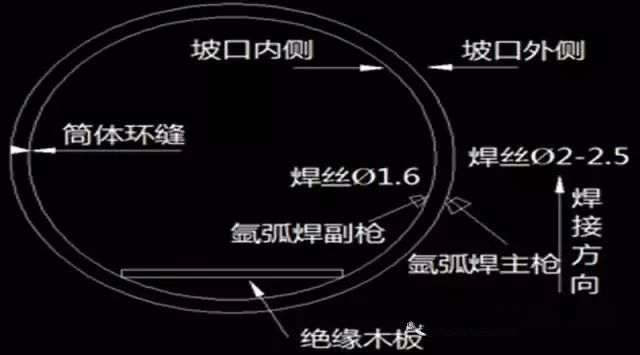

Ganga tana ɗaukar tsarin walda mai gefe biyu-baka na ƙasan walda na argon arc, kuma an yi aikin aikin ya zama tsagi mai siffa guda ɗaya na V.A cikin matsayi na tsaye, ana amfani da masu walda biyu da maɓuɓɓugan wutar lantarki masu zaman kansu guda biyu don haɗa ɓangarorin ciki da na waje na aikin tare da narkakken tafkin.waldi.Bayan waldi na ƙasa, ana cika cikawa da waldawar murfin tare da baka guda.Yana kawar da hanyar da ta gabata ta cika argon a gefen baya kuma yana rage tsarin tsaftacewa na tushen a gefen baya;yana da kyakkyawan walƙiya kuma yana iya sarrafa tsayin weld ɗin baya;saboda ninki biyu yana ƙara ƙarfin motsawar tafkin narkakkar da ruwa na narkakkar tafki, zai iya sa narkakkar tafki cikakkiya Fusion yana rage lahani kamar haɗaɗɗen slag, pores, da shigar da bai cika ba;yana da halaye na ƙananan shigarwar zafi, ƙananan nakasar walda, rage yawan damuwa na haɗin gwiwa, kuma yana ƙaruwa sosai.

Bukatun taro

1.1 Yi amfani da dandamali na musamman yayin taro don ware shi daga sauran kayan ƙarfe kamar ƙarfe na carbon;kauce wa karce sakamakon karo a lokacin sufuri;Dole ne a yi amfani da majajjawa da kayan aiki na musamman, kamar bel na nailan, don ɗagawa, kuma an haramta igiyoyin ƙarfe na ƙarfe don guje wa ɓata saman ƙarfe.

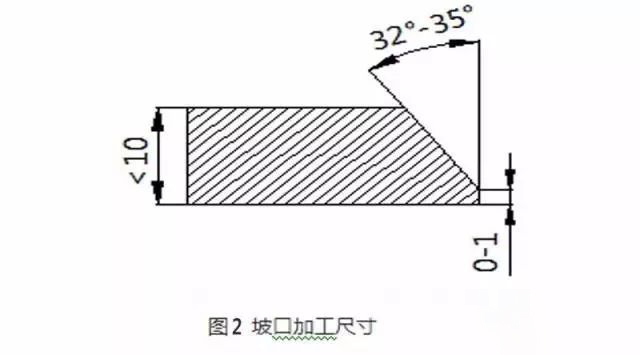

1.2 Zaɓi faranti masu dacewa daidai da buƙatun ƙira na zane-zane, ƙayyade ainihin girman kowane abu, yi amfani da yankan plasma ko machining don yanke kayan, kuma ya kamata a shirya tsagi ta hanyar mashin ko niƙa.Don sarrafawa, kai yana jujjuya shi da injin niƙa, kuma ana nuna takamaiman girman a hoto na 2

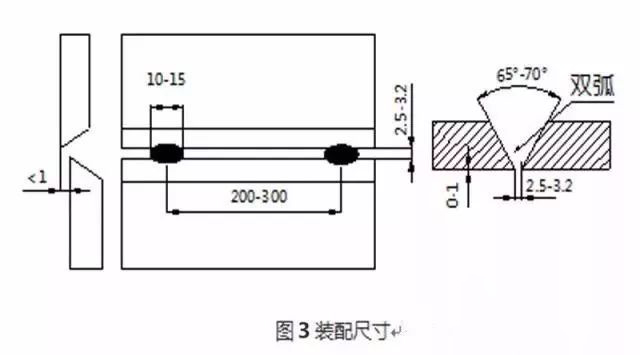

Bayan an gama aiki, ana amfani da mirgina wayoyi uku don sarrafa baka.An nuna girman girman taro a cikin Hoto 3. Tsabtace 10 ~ 15mm a bangarorin biyu na tsagi, ratar taro shine 2.5 ~ 3.2mm, ƙaddamar da farantin yana da ƙasa da 10% na kauri na bango, kuma ba fiye da 1mm ba. , ta amfani da argon baka waldi, tsawon 10 ~ 15mm, kauri 3 ~ 4mm.Ƙaddamarwar baka da ƙarewar baka dole ne a aiwatar da shi akan fuskar tsagi.Bayan haɗawa, yi amfani da goge baki don goge gaba da bayan mahaɗin solder don ganin kyalli.

1.3 Yayin taro, guje wa taron tilastawa don rage damuwa na ciki na abubuwan da aka gyara.Yi ƙoƙarin guje wa wasu abubuwa da za su gurɓata ko tashe saman allo.

An haramta buge baka ko walda ba da gangan da shigar da abubuwan wucin gadi a saman silinda.Filayen bangarorin biyu na walda yakamata su guji amfani da guduma don gyara shi.

Tsarin walda

2.1 Shiri kafin walda

Tsabtace tsatsa, danshi, mai, ƙura, da dai sauransu 10-15mm a bangarorin biyu na tsagi.

2.2 Zaɓin abubuwan da ake amfani da su na walda (duba Table 1)

| Ƙarfe na tushe | Wayar walda |

| Farashin 304 | Farashin ER308 |

| SUS 304L | Saukewa: ER308L |

| Farashin 316 | Farashin ER316 |

| SUS 316L | Saukewa: ER316L |

| Farashin 321 | Farashin ER321 |

Siffofin walda (duba Table 2)

| Base karfe kauri (mm) | Diamita na waya (mm) | Welding surface | Nau'in yanzu da polarity | Welding halin yanzu (A) | Gudun iskar gas (L/min) |

| 4-10 | Φ1.6 | Rashin tsagi | DC tabbatacce dangane | 20-50 | 6 ~ 10 |

| Φ2 ~ 2.5 | Fuskar bevel | DC tabbatacce dangane | 70-110 | 8 ~ 10 |

2.3 Kariyar walda

Zabi abin da ya dace waldi bisa ga farantin, yi amfani da Φ1.6mm waldi waya a cikin weld, waldi halin yanzu 20 ~ 50A, waje zabi Φ2 ~ 2.5mm waldi waya bisa ga kauri daga cikin farantin, waldi halin yanzu 70 ~ 110A, da kuma amfani da low halin yanzu azumi waldi ga bottoming.Cikowa da capping yadudduka yakamata su zaɓi hanyoyin walda kamar waldawar argon, walƙiya arc na lantarki, da walƙiyar garkuwar iskar gas CO2 bisa ga takamaiman yanayi.Lokacin da kauri farantin bai wuce 10mm ba, gwada kada a yi amfani da walda ta atomatik ta nutse.

2.4 Binciken walda

Bayan awanni 48 na walda, ana yin fim da launi mara lahani na kabu na walda.Wannan tsari yana ɗaukar walƙiya-arc-argon baka biyu don ƙasa, walƙiya argon don cika murfin murfin, yin fim ɗin waldi da gwajin mara lahani na canza launi duk sun cancanci, kuma gwajin lanƙwasawa, gwajin ƙarfin ƙarfi da gwajin lalata intergranular duk sun haɗu da ƙayyadaddun alamomi.

2.5 Magani bayan walda

Bayan gwaje-gwajen marasa lalacewa da gwajin ƙarfin, ana yin ƙwanƙwasa da jiyya na wuce gona da iri akan walda da kusa da wurin kabu.

Tsarin ƙasa mai gefe biyu-baka argon baka waldi na bakin karfe yana ɗaya daga cikin ingantattun hanyoyin walda.A matsayin babban inganci, ceton makamashi, inganci mai inganci da tsarin waldawa na tattalin arziki, walƙiya biyu-baka yana da kyakkyawan fatan aikace-aikacen a cikin samarwa na ainihi.

Lokacin aikawa: Juni-13-2022