Ogo ịgbado ọkụ nke ịgbado ọkụ nke igwe anaghị agba nchara tank mmiri na-emetụta ozugbo nchekwa nke arịa nrụgide.Enwere ọtụtụ ụzọ ịgbado ọkụ, argon arc welding bụ otu n'ime ụzọ ịgbado ọkụ dị mma, mana mgbe dayameta dị karịa 800mm na olu dịtụ ukwuu, nchekwa nchekwa argon dị n'ime na-eweta ụfọdụ ihe isi ike ma na-abawanye ọnụ ahịa mmepụta.A na-eji usoro ịgbado ọkụ abụọ-arc argon arc maka ịgbado ọkụ nke oghere okirikiri na ogologo ogologo nke akpa, nke na-eme ka ịdị mma ịgbado ọkụ na ịgbado ọkụ na-arụ ọrụ nke ọma ma na-ebelata ọnụ ahịa mmepụta.

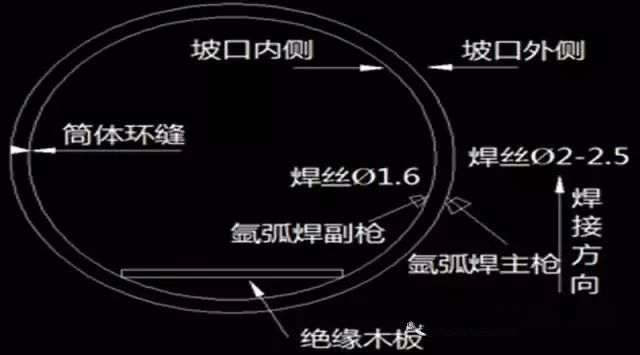

gbọmgbọm ahụ na-anabata usoro ịgbado ọkụ nke argon arc nwere akụkụ abụọ nwere akụkụ abụọ, yana arụ ọrụ ahụ ka ọ bụrụ oghere nwere akụkụ V nwere otu akụkụ.Na vetikal ọnọdụ, abụọ welders na abụọ nọọrọ onwe ike isi iyi na-eji jikọọ n'ime na mpụta akụkụ nke workpiece na a wụrụ awụ ọdọ mmiri.ịgbado ọkụ.Mgbe ịgbado ọkụ nke ala, ndochi na mkpuchi mkpuchi na-eji otu arc mechie.Na-ewepụ usoro gara aga nke na-ejuputa argon n'akụkụ azụ ma belata usoro nhicha mgbọrọgwụ n'akụkụ azụ;ọ nwere ezigbo weldability na ike n'ụzọ dị irè ịchịkwa elu nke agbara n'akụkụ weld;n'ihi na arc okpukpu abụọ na-eme ka ike na-akpali akpali nke ọdọ mmiri a wụrụ awụ na mmiri nke ọdọ mmiri a wụrụ awụ, ọ nwere ike ime ka ọdọ mmiri a wụrụ awụ zuru ezu Fusion na-ebelata ntụpọ dị ka ntinye slag, pores, na ntinye ezughị ezu;o nwere njiri mara nke obere ntinye ọkụ, obere nrụrụ ịgbado ọkụ, belata nrụgide nkwonkwo, yana ịba ụba nke ukwuu.

Mkpa mgbakọ chọrọ

1.1 Jiri ikpo okwu pụrụ iche n'oge mgbakọ na-ekewapụ ya na ihe ndị ọzọ ígwè dị ka carbon ígwè;zere ntancha nke nkukota kpatara n'oge njem;A ghaghị iji èbè na ihe ndozi pụrụ iche, dị ka eriri nylon, maka ibuli elu, machibidokwa eriri igwe nchara ka ọ ghara ịcha elu igwe ahụ.

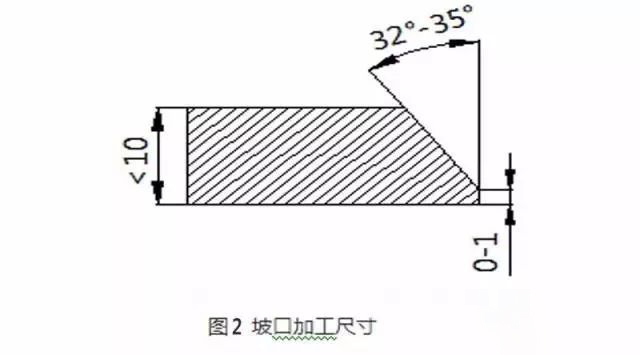

1.2 Họrọ efere ndị ruru eru nke ọma dabere n'ihe achọrọ imewe nke eserese, chọpụta nha nke ihe ọ bụla, jiri ịkpụ plasma ma ọ bụ ihe eji egbutu ihe, a ga-edozikwa oghere ahụ site na iji igwe ma ọ bụ ụzọ egweri.Maka nhazi, onye na-egweri na-ekpu isi ya, a na-egosipụtakwa akụkụ ndị akọwapụtara na foto 2

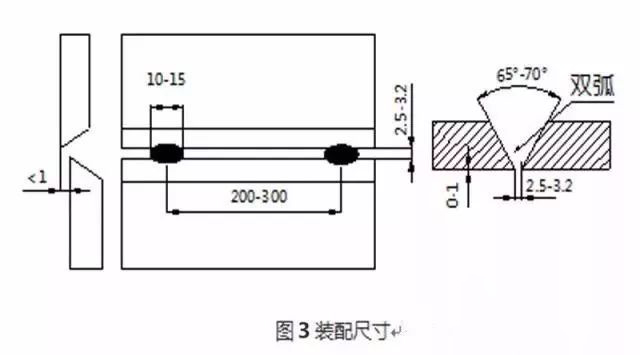

Mgbe emechara nhazi ahụ, a na-eji eriri waya atọ eme ihe maka nhazi arc.E gosipụtara nha mgbakọ na eserese 3. Na-ehichapụ 10 ~ 15mm n'akụkụ abụọ nke oghere ahụ, oghere mgbakọ bụ 2.5 ~ 3.2mm, nkwụsị nke efere ahụ na-erughị 10% nke mgbidi mgbidi, ma ọ bụghị karịa 1mm , iji argon arc ịgbado ọkụ, ogologo 10 ~ 15mm, ọkpụrụkpụ 3 ~ 4mm.A ghaghị ime mmalite mmalite na njedebe arc na ihu uzo.Mgbe mgbakọ gasịrị, jiri polisher na-ehichapụ ihu na azụ nke nkwonkwo ihe na-ere ahịa iji hụ ihe na-egbuke egbuke.

1.3 N'oge mgbakọ, zere mgbakọ mmanye iji belata nrụgide dị n'ime nke akụrụngwa.Gbalịa izere ihe ndị ọzọ na-emerụ ma ọ bụ na-akpụcha elu nke osisi ahụ.

Amachibidoro ịkụ arcs ma ọ bụ weld na-enweghị usoro ma wụnye ihe ndị na-adịru nwa oge n'elu cylinder ahụ.Ebe dị n'akụkụ abụọ nke weld kwesịrị izere iji hama mee ya.

Usoro ịgbado ọkụ

2.1 Nkwadebe tupu ịgbado ọkụ

Hichaa oyi akwa nchara, mmiri, mmanụ, ájá, wdg 10-15mm n'akụkụ abụọ nke uzo.

2.2 Nhọrọ nke ihe eji agbado ọkụ na-ejikarị (lee tebụl 1)

| Igwe ala | waya ịgbado ọkụ |

| Sus 304 | ER 308 |

| SUS 304L | ER 308L |

| Sus 316 | ER 316 |

| Sus 316L | ER 316L |

| Sus 321 | ER 321 |

Mpempe akwụkwọ ịgbado ọkụ (lee Tebụl 2)

| Ọkpụrụkpụ igwe ntọala (mm) | Dayameta waya (mm) | N'elu ịgbado ọkụ | Ụdị ugbu a na polarity | Mgbado ọkụ ugbu a (A) | Orufe gas (L/min) |

| 4-10 | Φ1.6 | Na-abụghị groove | DC nti njikọ | 20-50 | 6 ~ 10 |

| Φ2 ~ 2.5 | Ihu bevel | DC nti njikọ | 70-110 | 8-10 |

2.3 Akpachara anya ịgbado ọkụ

Họrọ ihe kwesịrị ekwesị ịgbado ọkụ dị ka efere, iji Φ1.6mm ịgbado ọkụ waya n'ime weld, ịgbado ọkụ ugbu a 20 ~ 50A, n'èzí họrọ Φ2 ~ 2.5mm ịgbado ọkụ waya dị ka ọkpụrụkpụ nke efere, ịgbado ọkụ ugbu a 70 ~ 110A, na-eji. obere ugbu a ngwa ngwa ịgbado ọkụ maka bottoming.Ndochi na mkpuchi mkpuchi kwesịrị ịhọrọ ụzọ ịgbado ọkụ dị ka argon arc welding, electrode arc welding, na CO2 gas na-echebe ịgbado ọkụ dị ka ọnọdụ akọwapụtara.Mgbe ọkpụrụkpụ efere na-erughị 10mm, gbalịa ka ị ghara iji submerged arc akpaka ịgbado ọkụ.

2.4 nyocha ịgbado ọkụ

Mgbe awa 48 nke ịgbado ọkụ gasịrị, a na-eme ihe nkiri na agba na-adịghị emebi emebi nke eriri ịgbado ọkụ.Usoro a na-anabata ịgbado ọkụ abụọ-arc argon maka ịkụ ala, ịgbado ọkụ argon arc maka imeju mkpuchi mkpuchi, ịgbado ọkụ na nnwale na-adịghị emebi agba nke agba niile tozuru oke, na nnwale ịgbado, ule ike tensile na ule corrosion intergranular niile na-ezute. kpọmkwem egosi.

2.5 ọgwụgwọ weld mgbe e mesịrị

Mgbe ule na ike na-adịghị emebi emebi, a na-eme ọgwụgwọ pickling na passivation na weld na mpaghara dị nso.

Usoro ịgbado ọkụ nke igwe anaghị agba nchara nke nwere akụkụ abụọ nwere akụkụ abụọ arc bụ otu n'ime ụzọ ịgbado ọkụ kacha mma.Dị ka a elu-arụmọrụ, ike-azọpụta, elu-edu na echekwa usoro ịgbado ọkụ, abụọ-arc ịgbado ọkụ nwere ezi ngwa atụmanya na n'ezie mmepụta.

Oge nzipu: Jun-13-2022