Qhov vuam zoo ntawm vuam seam ntawm stainless hlau siab dej tank ncaj qha cuam tshuam rau kev nyab xeeb ntawm lub nkoj siab.Muaj ntau txoj hauv kev vuam, argon arc vuam yog ib txoj kev vuam zoo tshaj plaws, tab sis thaum txoj kab uas hla ntau dua 800mm thiab qhov ntim kuj loj, qhov kev tiv thaiv sab hauv argon filling coj qee qhov teeb meem thiab nce tus nqi tsim khoom.Ob chav-arc argon arc vuam txheej txheem yog tsuas yog siv rau cov vuam ntawm lub voj voog ncig thiab cov kav ntev ntawm lub thawv, uas ua kom cov vuam zoo thiab vuam efficiency thiab txo cov nqi tsim khoom.

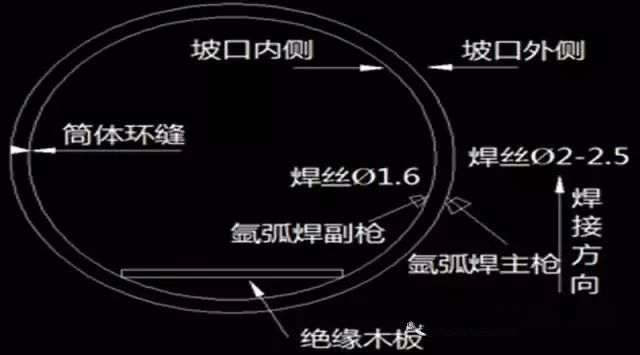

Lub thoob txais cov txheej txheem ob-sided ob-arc bottoming vuam txheej txheem ntawm argon arc vuam, thiab cov khoom ua haujlwm tau ua rau hauv ib qho V-shaped zawj.Nyob rau hauv txoj hauj lwm ntsug, ob lub welders thiab ob lub zog ywj pheej yog siv los txuas rau sab hauv thiab sab nrauv ntawm lub workpiece nrog lub pas dej ua ke.vuam.Tom qab vuam hauv qab, qhov txhaws thiab npog vuam yog ua tiav nrog ib qho arc.Tshem tawm cov txheej txheem yav dhau los ntawm kev sau argon ntawm sab nraub qaum thiab txo cov txheej txheem tu hauv paus rau sab nraub qaum;nws muaj qhov zoo weldability thiab tuaj yeem tswj qhov siab ntawm qhov rov qab sab weld;vim tias ob chav arc nce lub peev xwm ntawm lub pas dej molten thiab fluidity ntawm lub pas dej molten, nws tuaj yeem ua rau lub pas dej molten tag nrho Fusion txo qhov tsis xws luag xws li slag inclusions, pores, thiab tsis tiav kev nkag;nws muaj cov yam ntxwv ntawm cov khoom siv hluav taws xob me me, vuam me me deformation, txo kev sib koom ua ke kev ntxhov siab, thiab nce kev nkag mus.

Cov kev cai sib dhos

1.1 Siv lub platform tshwj xeeb thaum sib dhos kom cais tawm ntawm lwm cov ntaub ntawv hlau xws li carbon steel;zam kev khawb los ntawm kev sib tsoo thaum lub caij tsheb thauj mus los;tshwj xeeb slings thiab fixtures, xws li nylon siv, yuav tsum tau siv rau nqa, thiab steel hlau ropes yog nruj me ntsis txwv tsis pub kom tsis txhob khawb cov hlau nto.

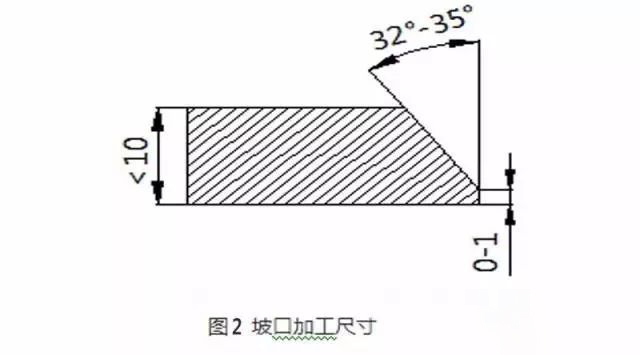

1.2 Xaiv cov phiaj xwm tsim nyog raws li qhov tsim nyog ntawm cov duab kos, txiav txim siab qhov loj me ntawm txhua yam khoom siv, siv cov plasma txiav los yog machining los txiav cov khoom, thiab cov grooves yuav tsum tau npaj los ntawm kev siv tshuab lossis kev sib tsoo.Rau kev ua, lub taub hau yog beveled los ntawm ib tug grinder, thiab qhov tshwj xeeb qhov ntev yog qhia nyob rau hauv daim duab 2

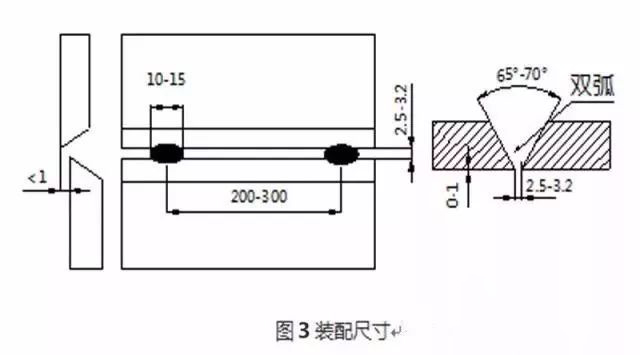

Tom qab ua tiav, peb-xaim dov yog siv rau kev ua arc.Kev sib dhos loj yog qhia hauv daim duab 3. Ntxuav 10 ~ 15mm ntawm ob sab ntawm qhov zawj, qhov sib dhos sib dhos yog 2.5 ~ 3.2mm, qhov offset ntawm lub phaj yog tsawg dua 10% ntawm phab ntsa thickness, thiab tsis ntau tshaj 1 hli. , siv argon arc vuam, ntev 10 ~ 15mm, thickness 3 ~ 4mm.Lub arc pib thiab arc termination yuav tsum tau nqa tawm ntawm lub ntsej muag zawj.Tom qab sib dhos, siv lub polisher polish rau pem hauv ntej thiab nraub qaum ntawm cov pob qij txha kom pom cov luster.

1.3 Thaum lub sij hawm sib dhos, tsis txhob yuam kev sib dhos kom txo tau qhov kev ntxhov siab sab hauv ntawm cov khoom.Sim zam kom tsis txhob muaj lwm yam khoom sib kis lossis khawb qhov chaw ntawm lub rooj tsavxwm.

Nws yog txwv tsis pub randomly ntaus arcs los yog randomly weld thiab nruab ib ntus Cheebtsam ntawm lub tog raj kheej nto.Qhov chaw ntawm ob sab ntawm lub vuam yuav tsum tsis txhob siv rauj los kho nws.

Vuam txheej txheem

2.1 Kev npaj ua ntej vuam

Ntxuav cov txheej xeb, noo noo, roj, plua plav, thiab lwm yam. 10-15mm ntawm ob sab ntawm qhov zawj.

2.2 Kev xaiv cov khoom siv vuam siv feem ntau (saib Table 1)

| Base hlau | Vuam hlau |

| TIAB SA 304 | TIAB SA 308 |

| SUS 304 L | TSI 308L |

| TIAB SA 316 | TIAB SA 316 |

| SUS 316L | TIAB SA 316L |

| TIAB SA 321 | TIAB SA 321 |

Welding parameters (saib Table 2)

| Base hlau thickness (mm) | Hlau txoj kab uas hla (mm) | Vuam nto | Tam sim no hom thiab polarity | Vuam tam sim no (A) | Gas ntws (L / min) |

| 4-10 | Φ1.6 | Tsis-groove | DC kev sib txuas zoo | 20 ~ 50 | 6 ~ 10 |

| Φ2 ~ 2.5 | Bevel ntsej muag | DC kev sib txuas zoo | 70-110 : kuv | 8 ~ 10 |

2.3 Vuam ceev faj

Xaiv cov khoom siv vuam tsim nyog raws li lub phaj, siv Φ1.6mm vuam hlau hauv qhov vuam, vuam tam sim no 20 ~ 50A, sab nraud xaiv Φ2 ~ 2.5 hli vuam hlau raws li lub thickness ntawm lub phaj, vuam tam sim no 70 ~ 110A, thiab siv. low tam sim no ceev vuam rau bottoming.Filling thiab capping txheej yuav tsum xaiv txoj kev vuam xws li argon arc vuam, electrode arc vuam, thiab CO2 roj shielded vuam raws li tej yam kev mob.Thaum lub phaj thickness tsawg dua 10 hli, sim tsis txhob siv submerged arc tsis siv neeg vuam.

2.4 Vuam tshuaj xyuas

Tom qab 48 teev ntawm vuam, zaj duab xis thiab xim tsis muaj kev puas tsuaj ntawm vuam seam yog nqa tawm.Cov txheej txheem no tau txais ob-arc argon arc vuam rau hauv qab, argon arc vuam rau sau lub hau npog, vuam seam filming thiab tsis muaj kev puas tsuaj ntawm cov xim yog tag nrho cov tsim nyog, thiab cov kev xeem dabtsi yog khoov, tensile lub zog kuaj thiab intergranular corrosion test tag nrho raws li cov cim qhia.

2.5 Kev kho tom qab vuam

Tom qab kev sim tsis muaj kev puas tsuaj thiab kev sim lub zog, kev kho mob pickling thiab passivation yog ua nyob rau ntawm qhov vuam thiab qhov ze seam cheeb tsam.

Cov txheej txheem hauv qab ntawm ob sab ob sab argon arc vuam ntawm stainless hlau yog ib qho zoo tshaj plaws vuam txoj kev.Raws li kev ua haujlwm siab, kev txuag hluav taws xob, kev ua haujlwm zoo thiab kev lag luam vuam, ob chav arc vuam muaj kev thov zoo hauv kev tsim khoom tiag tiag.

Post lub sij hawm: Jun-13-2022